Smart Factory

Increased production efficiency through process automation

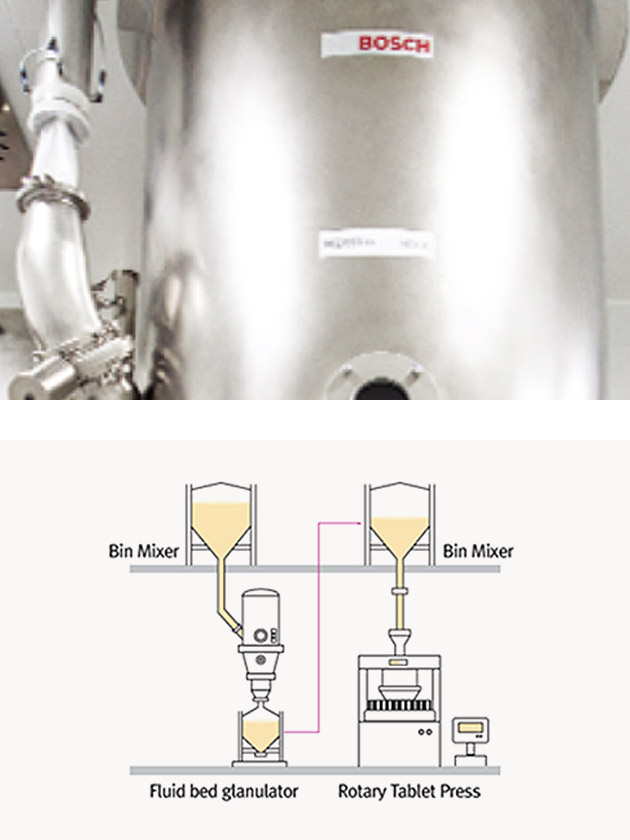

Oral Solid

- Features

- Manage production to warehouse through automated IT systems (QMS,LIMS,EMS)

- Dedicated facility for mass production of oral solid

- Capacity: 20Billion Tablets / Year

- Facilities

- Vertical Transfer System (VTS) Enclosed system to prevent cross-contamination, influx of any foreign materials, or tablet breakage

Vertical Transportation System (VTS) - Facilities for Tableting Multi-layered tablet machine, Tab-in-Tab machine, IR tablet machine

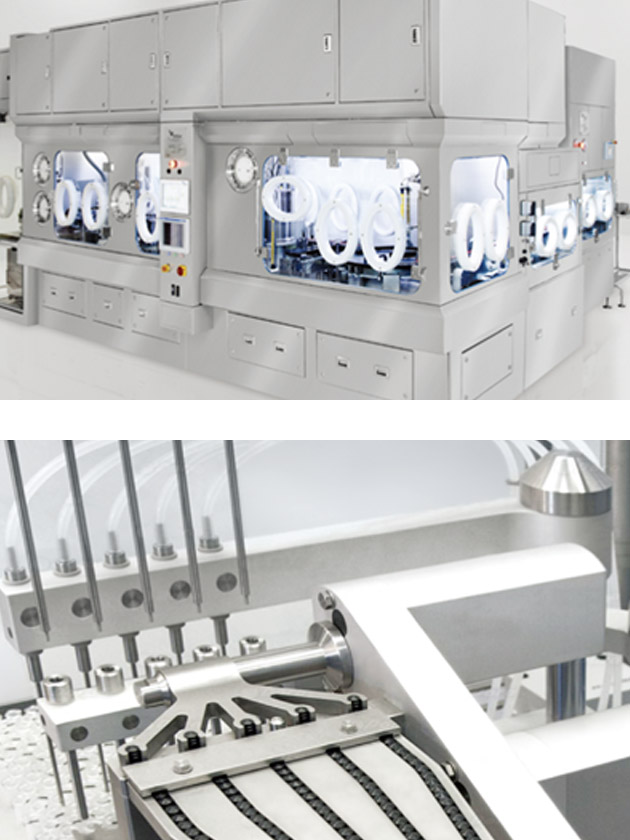

Depot Injection

- Features

- Equipped with Qualified Injection manufacturing facility

- First in Korea to equip Dual Chamber Syringe (DCS) charging line

- Capacity: 0.6Billion Vials / Year

- Facilities

- Equipped with facilities equivalent to original’s manufacturing scale, which prevents quality variance occurring from facility difference

- Facilities serving wide manufacturing coverage: